German e-bike motor manufacturer Brose has won acclaim for its sustainable practices, namely for its remanufacturing of old drive units that can be bought at a lower cost to new pieces. They’ve been doing this for a few months, with 'Reman Drive' units being available to buy from November.

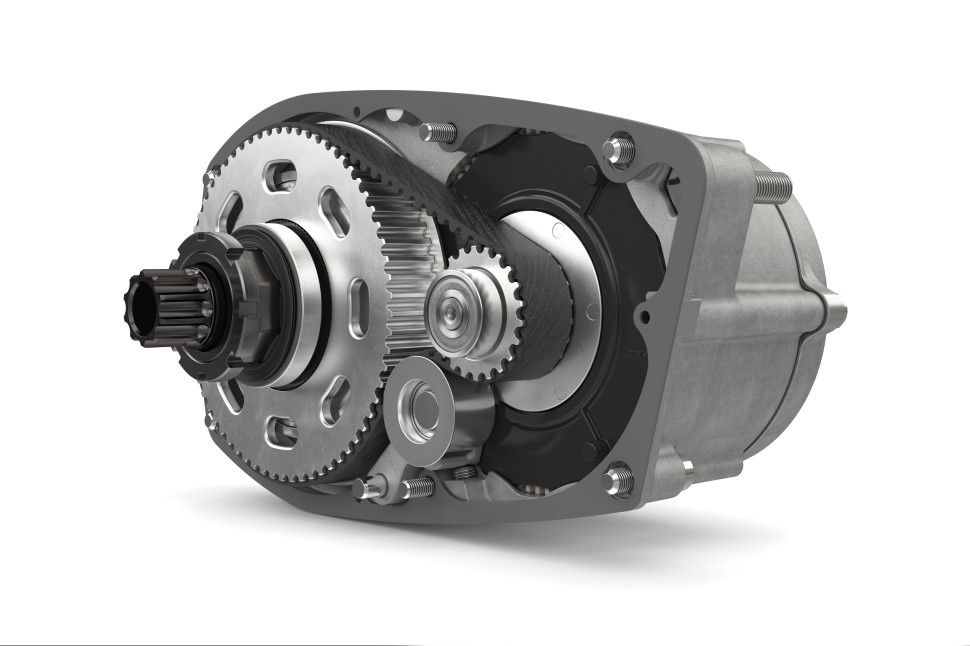

The ‘Reman Drive’ (remanufactured drive) as they’re calling it takes five components from old units to be reconditioned. Then they’re cleaned, tested and reassembled into the Brose Reman Drive unit. Brose is offering a guarantee on the motors for two years, and are said to be “significantly cheaper” than new units.

The Project Leader of Remanufacturing at Brose, Vincent Bahar commented:

“We are very proud of our self-designed method, which we have already compared with the contents of DIN SPEC 91472. In that process, we also recognized potential for further developing the specification. The meeting encourages us in our approach and should be an incentive for even more sustainability in the entire e-bike industry."

From a sustainability standpoint, the Reman Drive production is claimed to save 21kg of Co2 compared to manufacturing new parts. The remanufacturing division is part of their

The magnesium motors have been available to purchase since August, and the aluminium series is expected to follow in early 2024.