Bike Europe reported recently on industry reaction to the new European Batteries Regulation, commenting that, "Insiders expect the regulation is going to shake up the European e-bike battery market and the industry is not yet ready in finding an answer to this challenge."

The nature of 'the challenge' was highlighted by Claus Fleischer, managing director of Bosch eBike Systems.

Commenting on one particular aspect of the forthcoming battery regulations, Fleischer said: "... for safety reasons, we regard the requirements for the removability and replaceability of individual cells from a battery pack as extremely critical and we see no real benefit as regards to sustainability."

Why is single-cell replacement a hot topic?

Before we get to the controversial bit, it's important to say that Bosch agreed with the elements of the regulations that will deal with, "performance and durability as well as for the declaration of a CO2 footprint of the battery pack and the introduction of specific collection systems in all member states." As the European Parliament details, there are also stipulations on 'used' batteries for minimum levels of materials recovered and the minimum levels of recycled content for use in new batteries - none of which appear particularly controversial for Bosch.

Whilst you might expect Bosch, as the high quality e-bike motor system market leader, to defend the status quo, there do appear to be sound technical reasons behind its protestations. We asked for a second opinion from someone who has unrivalled experience in the technical aspects of recycling and repair of e-bike batteries, Hannes De Jong, MD of Heskon, one of the biggest - if not the biggest - e-bike battery repair, refurbishment and recycling companies in Europe.

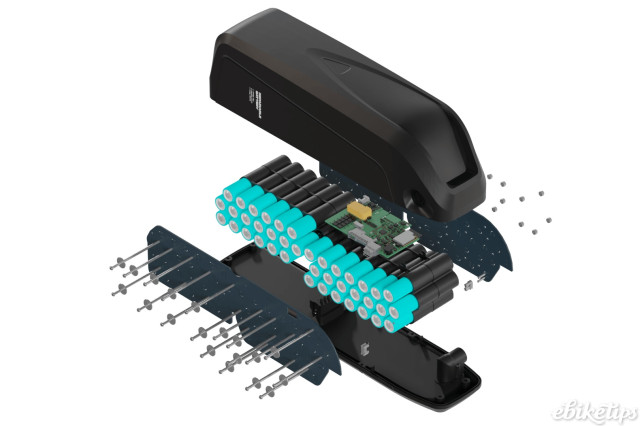

De Jong said: "In our experience, a single 'broken' cell is almost never the issue with a broken battery. In the first 1-4 years of its life an e-bike battery has issues external to the cells - a broken casing, broken connectors, broken BMS (battery management system chip) and broken fuses are the main culprits we have seen. After four years the overall performance (range potential) of a battery pack often declines meaning all cells are getting older and the full corepack needs to be changed rather than a single cell."

Less recycling, more repair?

This doesn't mean the new regulations couldn't be a huge agent for change for the better, however.

De Jong again: "The situation today is that bike brands purchase their batteries from battery manufacturers. If issues occur within the industry-standard two-year warranty period, the usual scenario is that the battery manufacturer provides either a credit note or swaps it with a new battery. This is the case in even the smallest of issues like a cracked casing, broken charge port connector or a broken BMS.

"In my professional opinion, these 'minor' issues can easily be repaired. Assuming such repairs will now be required by the new regulations, then yes, this will disrupt the current e-bike battery market when you take into account that on average 1% of all batteries fail in the first two years of warranty period - and many more in the 3-4 year period."

For context De Jong adds: "The estimate from the EU is that in 2030, there will be 30m light electric vehicle batteries on the EU market and 1% of 30m is 300,000 batteries that will be otherwise scrapped."

If the regulations do what they are intended to do and ensure that such simple repairs are effected rather than entire batteries sent for recycling then they will have done their job.

Gouach leading the way?

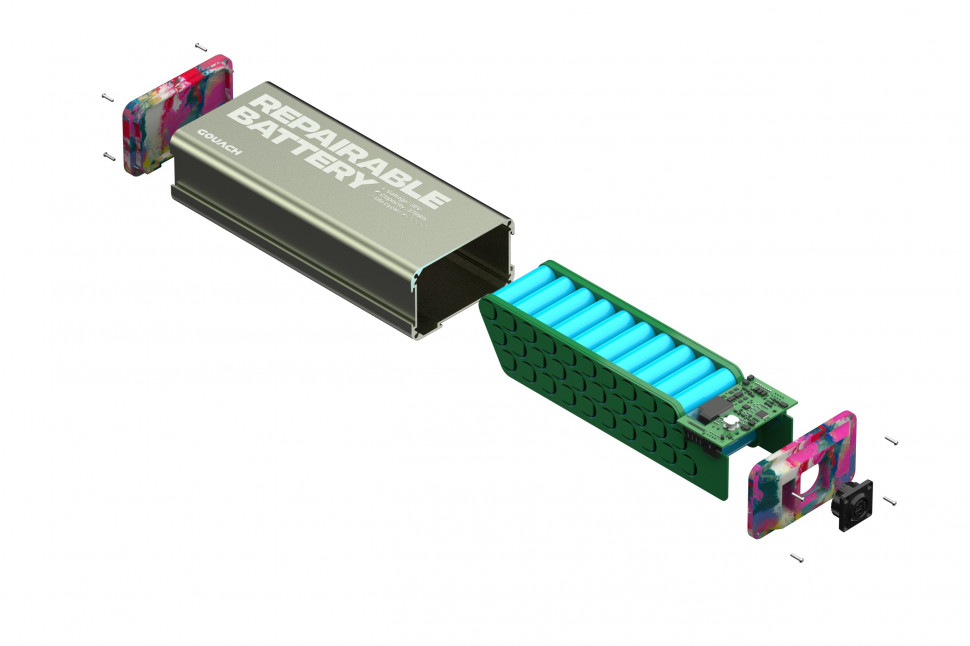

Clearly the legal requirement for individual cell replaceability (however you might define it) is not really seen as a major step forward in terms of sustainability by many in the industry. However, one company certainly do think it is the future and has planned their battery design around it.

We have already covered the development of Gouach's 'repairable in ten minutes' battery which features replaceable cells and their subsequent tussle with the giants of the industry.

Gouach stress the safety credentials of their system. "Advanced design developments have been made that incorporate contact plates and cell holders together, allowing for the safe removability and replaceability of individual defective cells. These models already passed the current necessary certifications (such as EN62133 and UN 38.3) offering a safer alternative to traditional welding."

Gouach stress that, "Some standards and quality assurance best practices will have to be set in place to ensure that local repairs are conducted properly, ensuring battery safety." That's to say they envisage repairs done locally by authorised local repair shops as part of a truly sustainable circular battery economy .

In addition to featuring quickly replaceable cells, Gouach say not only is their battery repairable but that it features Bluetooth and Wi-Fi connectivity for remote diagnosis. They also claim it has a carbon footprint up to four times less than a typical e-bike battery.

Perhaps a more truly sustainable path for batteries that aren't up to the rigorous demands of powering e-bikes is power storage. Some electric car batteries are 'repurposed' for storage of renewable electricity when their usable range drops below what is really practical.

Gouach say, "Our study over hundreds of discarded batteries has shown that 70% of a battery's cells are still in near-perfect condition when they are thrown away or crushed to become 'black mass'. With the right design, these functional cells can be reused in other batteries, for robotics or solar panel energy storage, for instance. By replacing individual cells ('battery regeneration'), as opposed to throwing away and replacing an entire battery pack, we drastically reduce our economical and environmental footprint. It is high time we created a functional reuse loop in Europe and avoided wasting our finite resources."

For more information on the current situation, take a look at our guide on whether you should repair, recycle, refurbish or replace your old e-bike battery.